What Features Should a Good Pallet Jack Have?

Features to Look For

Believe it or not, customers can be very territorial when it comes to which pallet trucks they'll consistently buy. Some are loyal to a particular brand; some will only use a particular style. Some will pay top dollar for what they consider a “premium” truck, while others skimp and only buy the “disposable” kind.

And yes, there are many customers out there who only buy a truck if it comes in their preferred color. That's all well and good; customers can buy whatever they want to based on their own – sometimes peculiar – tastes and requirements. But, there certainly are comparative advantages some pallet jacks have that others do not. Below are some key features every good pallet truck should have (and every good pallet truck salesperson should know about!)

Adjustable Push Rods – for Healthy and Balanced Forks

How many times have you walked through a Walmart or a Home Depot and seen an employee moving a pallet of stock with most of it stacked on one side of the jack? How many times have you seen or heard of someone moving or lifting a very heavy piece of machinery by putting one fork of a pallet jack underneath and pumping it up? Examples like these are common. And while a jack can reasonably do these things, they are not meant to.

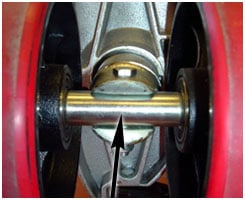

Moving or lifting an imbalanced load causes undue stress on the individual forks and the frame itself. The result: a cracked or bent frame and one fork sitting higher than the other. A good number of people will typically look at their warped pallet truck and think that it's time to throw it away and buy a new one. As good as that is for pallet jack sales, there is another option. Many a pallet truck for sale today features Adjustable Push Rods. The push rod is the long, tubular piece of steel that sits underneath each fork and raises it up when the handle is pumped.

| Push-Rods |  |

Push-Rods |

The benefit to having a truck with adjustable push rods is that each individual fork's height can be manually adjusted. If there is an imbalance, simply flip the truck over, remove one push rod and thread it a bit looser or tighter, reinstall it, and the truck is back in functional, balanced shape. The whole process takes about 10-15 minutes, but its easy field servicing that can mitigate having to completely replace your truck.

When a pallet truck is pumped, it is essentially “pushing” the push rod, raising or lowering the load rollers accordingly, which raises and lowers the forks. The push rod threads into the “joint,” as pictured. By removing the joint/push rod assembly, one can twist it looser or tighter by hand. The further you thread it in, the higher the fork will sit, and vice versa.

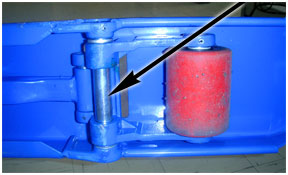

Articulating Axle – Amazingly, NOT a Standard Feature on All Pallet Trucks

Many pallet trucks on the market offer an articulating axle. What may shock and surprise you though, is that many pallet trucks don't. Why is this so surprising? Quite frankly, an articulating axle will mean the difference between your fragile and carefully packaged load arriving to its destination intact, or in pieces. Similar to a car or truck, the pallet truck axle is the fixed, central shaft that connects the two rolling steer wheels, maintaining both their balance and their uniformity. An articulating axle has some “wiggle” room though; it moves up and down depending on the surface you're rolling your truck over, and it acts as a shock absorber of sorts when rolling over a rough or un-smooth surface, and will minimize the bumps and jostles sustained by the load while in transit.

|

|

| Articulating Axle | Non-Articulating Axle |

Trucks without an articulating axle (and there are many out there) will have stiff and rigid steer wheels that do not handle bumps well, or at all. Something as simple as this makes a huge difference when safe transport of a pallet or skid needs to be considered. Why some trucks have fixed axles is a question we may never find an answer to…

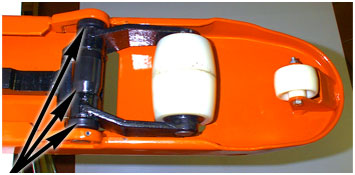

Entry Rollers – How to Avoid the Dreaded “Push Effect”

Most economically priced pallet trucks have an entry ramp. They help the truck enter a pallet by having the ramp slide over the pallet bottom board. They are basic and they are cheap and they do a pretty average job. The problem with ramps though is that sometimes, when the pallet is light enough, you go to push your jack into the pallet and you end up pushing the pallet forward in the effort. So you try again with a bit more speed – same result. It can take a few tries before you actually get the truck in. That's typically how entry ramps work.

|

Entry Ramp vs. Entry Roller |  |

Enter, the entry roller. Where ramps tend to get held up against the bottom board, the roller will easily glide over it, allowing quick and easy pallet entry. It's a small added feature, but it's well worth it for the marginal extra cost, the efficiency it will add, and the frustration it will alleviate for those who end up “pushing” their pallets halfway across their warehouse.

Exit Rollers – As the Name Implies…

Whereas entry rollers allow for easier pallet entry, exit rollers have the opposite advantage: easier pallet exit. Pulling a truck from an empty pallet is not always easy; far too often you'll either not have enough momentum to get it out, our you'll drag the pallet along with the truck. Exit rollers provide that additional rolling assistance needed to easily get the truck out. Simple and efficient, though sometimes hard to spot, a truck with exit rollers is worth investing in.

|

| Exit Rollers: one primary and two secondary |

| No Exit Rollers |

|

When shopping around, keep a close eye out for the features listed above. Some pallet jacks command a higher price, partly because they are equipped with these features. They are worth the money and will add both longevity and functionality, ultimately saving you money on costly repairs and replacements over time.

Steve Guagliano Jr. followed his father into the material handling industry and has over 10 years of direct field sales experience, technical services and project management expertise. Steve is an expert in manual pallet trucks, high-lift stackers, and electric walkie and rider units.