Why Do I Need Span Track for My Operation?

Due to just-in-time inventory management trends in warehousing and distribution, the ability to integrate span track conveyor into pallet rack is a very powerful and flexible tool.

Span track is a type of carton flow rack conveying system that uses gravity to move packaged or boxed product from the rear/input end of a storage system, to the front/picking side. This material handling solution addresses labor and space costs, the two major cost drivers in distribution, warehouse and manufacturing facilities. Span track systems work best for medium and slower moving SKU’s, usually about 50-70% of a facility’s inventory.

Why should I consider Span Track?

Up to 60% of a distributor’s total labor is from order picking. Static storage systems like pallet rack and industrial shelving are most common in today’s facilities. Because products stored in these systems are fixed, picking requires bending, reaching and pulling, adding time and strain to the pick process. Dynamic storage systems like span track conveyor reduce the inefficiencies and ergonomic concerns of static systems.

When an employee picks the front product, the remaining product flows to the picking point. Span track increases pick rates up to 30% versus static storage, all while eliminating bending, reaching and pulling. In a static storage system, an order picker spends up to 80% of his or her time traveling. Span track systems increase pick efficiency by reducing travel time by 30-80% compared to a static storage pick process. “LIFO” last in, first out Static Storage

- Unreachable space

- Head clearance wasted space

- Poor visibility

- LIFO stock rotation

- Unsafe picks

“FIFO” first in / first out Dynamic Span Track Storage

“FIFO” first in / first out Dynamic Span Track Storage

- Increased facings, extra levels

- Easy to restock

- Product always up front

- Full depth storage

- FIFO stock rotation

- Safe, ergonomic picks

Adding Span Track to Your New or Existing Pallet Rack.

Installing span track in the lower levels of any pallet rack system allows you reduce costs by using existing frames. Also, unlike plastic wheel carton flow systems, you don’t need shelves or intermediate supports to add span track to your pallet rack. Drop in installation is 33% faster compared with installing carton flow rails. Span track also has high flexibility; you can move lanes easily and quickly to reslot SKU’s.

Rollers: Span Track vs. Carton Flow

Span track rollers have two advantages over carton flow wheels: longer life and better flow. Made of galvanized steel side channels, span track rollers can take the abuse of active storage facilities, handling loads up to 50 lbs. per ft. Additionally, span track rollers are typically 9″, 12″ and 15″ wide, providing 300% more contact with product than 1″ wide plastic carton flow wheels. Because of this, boxes and cartons flow smoother with fewer hang-ups on span track rollers.

Typical Span Track Applications

The industry you are in and the way you operate (full case, split case, each pick, fork truck aisle, etc.) will determine which model or combination of models is right for you. Some typical applications are shown below.

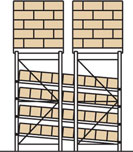

Add span track to single or double deep pallet racks without the need for shelves or intermediate supports.

Add span track to single or double deep pallet racks without the need for shelves or intermediate supports.

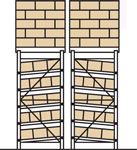

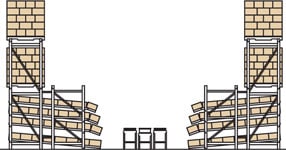

Span track can be configured as a push back application by installing in back-to-back pallet racks.

Span track can be configured as a push back application by installing in back-to-back pallet racks.

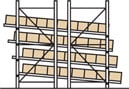

This layback arrangement of high profile span track produces a contoured profile for better loose pick access.

This layback arrangement of high profile span track produces a contoured profile for better loose pick access.

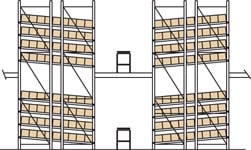

Increase storage capacity while enhancing the features of your pallet rack and mezzanine picking module by adding span track.

Increase storage capacity while enhancing the features of your pallet rack and mezzanine picking module by adding span track.

A typical pick module system with span track in pallet rack leading to a conveyor take away.

A typical pick module system with span track in pallet rack leading to a conveyor take away.