What Exactly Is Warehouse Automation?

If you’ve heard of automation, but you’re not sure exactly what that means, Warehouse1 is ready to walk you through it. In a fast-paced world where efficiency, accuracy, and expediency is expected, automation systems are here to stay. The future is now.

Defining Warehouse Automation

The warehouse industry was built on what we call manual material handling (MMH). This is where you depend on employees and temporary/seasonal employees to store, retrieve, and sort products. It’s often what comes to mind when people think about traditional warehouse jobs and workflows. This has positioned the warehouse as a crucial aspect of any healthy supply chain.

Automated material handling (AMH) introduces technologies that cut down the amount of manual labor that is needed in the warehouse. New hardwares and softwares like lifts, pallet shuttles, packers, conveyors, robotics, and more can be incorporated into your processes to make your warehouse work smarter and faster. There’s less walking and lifting, and more programming and virtual controlling.

Automated material handling (AMH) introduces technologies that cut down the amount of manual labor that is needed in the warehouse. New hardwares and softwares like lifts, pallet shuttles, packers, conveyors, robotics, and more can be incorporated into your processes to make your warehouse work smarter and faster. There’s less walking and lifting, and more programming and virtual controlling.

Automation changes the types of jobs and roles in your warehouse.

You can implement one automation system, or you can redesign an entire warehouse using AMH. The tools exist to help streamline, strengthen, and support processes all around the warehouse.

What Can Automation Do?

Every aspect of your warehouse can be automated. It’s important to map your process and/or material and assess your facility to determine where and how to implement automation.

Movement

With MMH, humans move the products either by manually lifting or operating carts, jacks, and forklifts. Automation systems can move products through the warehouse without anyone needing to lift or drive.

With MMH, humans move the products either by manually lifting or operating carts, jacks, and forklifts. Automation systems can move products through the warehouse without anyone needing to lift or drive.

Example: A conveyor or autonomous mobile robot (AMR) carries totes or boxes from receiving to the picking area instead of someone driving pallets by hand.

Storage

Automation can place products into storage locations efficiently and safely, and it can help ensure you’re using the full height of your warehouse and taking advantage of the full cubic feet.

Automation can place products into storage locations efficiently and safely, and it can help ensure you’re using the full height of your warehouse and taking advantage of the full cubic feet.

Example: An automated storage and retrieval system (ASRS) uses cranes or shuttles to lift pallets into high-bay racking, maximizing vertical space.

Retrieval

Automation can quickly bring products out of storage when needed, allowing you to keep up with increases in volume and seasonal spikes. This can be configured for FIFO or LIFO retrieval so the units you need get pulled first.

Automation can quickly bring products out of storage when needed, allowing you to keep up with increases in volume and seasonal spikes. This can be configured for FIFO or LIFO retrieval so the units you need get pulled first.

Example: A goods-to-person system retrieves a tote from storage and delivers it directly to a picker’s workstation, eliminating walking and searching.

Picking

Automation can identify and select the right item for each order. AI, robotics, and analytics are making automation reliable and fast.

Automation can identify and select the right item for each order. AI, robotics, and analytics are making automation reliable and fast.

Example: A robotic picking system highlights or grabs the exact item needed based on the SKU, ensuring accuracy and speeding up fulfillment.

Packing

Automation can prepare orders for shipment and handle tasks like layering, loading boxes/units on a pallet, and stretch wrapping.

Automation can prepare orders for shipment and handle tasks like layering, loading boxes/units on a pallet, and stretch wrapping.

Example: An ASRS crane controlled by pre-programmed software locates a pallet in a high-bay rack, pulls it from storage, and delivers it to a conveyor for transport to shipping.

Shipping

Automation can sort, weigh, and route outgoing orders within a short amount of time.

Automation can sort, weigh, and route outgoing orders within a short amount of time.

Example: A sortation conveyor scans each box’s barcode and directs it to the correct outbound dock for its carrier or route, which ultimately leads to the client getting notification on the status of the item until it’s delivered.

Benefits of Warehouse Automation

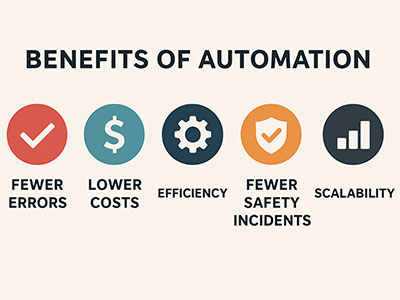

It’s common for warehouse managers to be hesitant about incorporating new technologies into the warehouse, but automation can bring several positive changes and benefits to both your warehouse and your company as a whole:

It’s common for warehouse managers to be hesitant about incorporating new technologies into the warehouse, but automation can bring several positive changes and benefits to both your warehouse and your company as a whole:

- Fewer errors: Automation can reduce human mistakes and increase consistent performance, which leads to client satisfaction.

- Lower operational costs: Automation helps you do more in less time, and decreases the cost of labor.

- Increased efficiency: Technology can speed up your warehouse, remove bottlenecks, and maximize your warehouse space.

- Safety: Workers report that automation reduces physical strain and reduces safety risks. There’s less walking and repetitive movements when automated systems do the work.

- Scalability: Today’s warehouse must keep up with the times; automated warehouses can handle more volume and are positioned to scale and keep up with demand.

What Areas of the Warehouse can Be Automated?

Every aspect of your warehouse could benefit from an automation system. Warehouse1 works with warehouse managers to assess unique needs and recommend solutions. Each warehouse is different, and warehouse automation is not a “one size fits all” solution. Some types of warehouse automation include:

- Automated storage and retrieval system (ASRS)

- Vertical lifts

- Pallet shuttles

- Robotics (AMRs)

- Conveyors

Financial Impact of Warehouse Automation

Customers often find that automation systems lower their costs in the long run. By maximizing the warehouse space and lowering dependency on manual labor, automation can help you cut and contain your costs, and help you increase your volume and output.

It’s important to build a business case where you can strategically assess costs and determine ROI before making automation changes. Remember: It’s OK to start small and pilot one zone before expanding to another.

Is Automation Right for You?

Transitioning from MMH to AMH systems is a big decision. It requires coordination and careful attention to the layout, current systems, equipment, and software your warehouse currently uses. Automation should improve and enhance your current systems, not disrupt it.

Transitioning from MMH to AMH systems is a big decision. It requires coordination and careful attention to the layout, current systems, equipment, and software your warehouse currently uses. Automation should improve and enhance your current systems, not disrupt it.

Our goal at Warehouse1 is to help you identify ways automation can help you deliver quicker, faster results with fewer errors and lower costs.

A few questions to ask yourself:

- Do you have the ability to cover the initial costs (equipment, software, integration, installation and training) as well as ongoing costs like maintenance, parts, data management, and software upgrades?

- Is your building ready and able to support automation? Consider clear height, floor loading, current layout, existing conveyors, etc.

- Is your current software integrated and able to incorporate new technologies?

- Is your order volume increasing? Automation is ideal when you have repetitive tasks and significant volume, with tight turnaround times and space constraints.

- Are you struggling to hire, train, or retain staff, or keep up with increasing wages? Are you facing an increased amount of workplace injuries or inaccuracies?

- Are you experiencing fulfillment delays?

If you answered “yes,” to any of the above, automation may be a great solution for you.

Contact Warehouse1 to Learn More!

Warehouse1 is an automation expert, and we have helped many warehouses incorporate successful automation systems into their spaces. We can help audit your warehouse and help you identify pain points, map workflows, and identify which products may help you now and in the future.

Contact us to learn how to maximize and speed up your warehouse.