Push Back Pallet Racking Systems

On the hunt for a warehousing solution that will help you make the most of limited space? Accomplishing this can be difficult when you're determined to maintain peak productivity. Thankfully, an excellent solution is available: push back pallet racking.

Push back pallet racking is one of the best options for boosting both flexibility and productivity in a variety of warehouse environments. When implemented correctly, these pallet storage systems optimize space while making a wide range of organization solutions easier to navigate and understand.

The result? Improved inventory management efficiency, plus a whole host of other benefits that we'll explore in detail below.

How Can We Help?

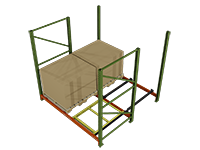

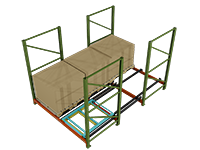

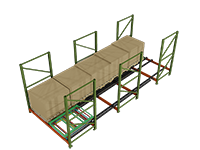

How Does Push Back Racking Work?

Push back pallet rack systems use carts and railing to make it easy to fill up your warehouse space. This system is a last-in-first-out (LIFO) solution, ideal for storing a limited number of SKUs with high-volume.

To load, lift drivers add a pallet in the front of the system on a rail cart. As more pallets are added to the system, the last one is pushed one space farther into the system. A gravity system makes unloading an easy task with gravity feeders that push the next pallet in line towards the loading/unloading space. Lift truck drivers always have a pallet ready for transfer in the first rack position in a push back pallet rack.

Benefits of These Systems

There's a lot to love about the push back approach, although it's more effective in some situations or sectors than others. The following are a few of the most compelling benefits to keep in mind if you're considering this option:

High-density storage. Push back racking is ideal in warehouses with limited space. Under this approach, it's possible to maintain high-density storage, as this setup is far more compact than other types of pallet racking. In many cases, push back racks make it possible to double storage as compared to standard racking systems.

High-density storage. Push back racking is ideal in warehouses with limited space. Under this approach, it's possible to maintain high-density storage, as this setup is far more compact than other types of pallet racking. In many cases, push back racks make it possible to double storage as compared to standard racking systems.- Diverse storage opportunities. Push back racking can be used for many types of items. It is one of the most versatile options available, making it a natural choice for enterprises that need to store multiple SKUs.

- Reduced operational costs. By improving storage density, push back racking systems limit the need for expanded warehouses. This, in turn, can keep operational costs to a minimum, even as an enterprise's product throughput and volume increase substantially.

- Higher selectivity. The push back approach echoes the single-selective pallet rack in that mobile carts are placed on rails for every row. In this way, it maintains the advantages of selectivity without compromising on storage density.

- Faster operations. The inherent selectivity of push back systems allows them to achieve impressive efficiency as compared to other high-density solutions.

- Avoid the honeycomb effect. Many pallet racking systems succumb to the honeycomb effect, in which a limited range of items are kept in specific storage areas. This can result in poorly used space, thereby requiring the warehouse to maintain more space to store fewer items.

- Avoid damage. Drive-in racks can be prone to damage when they come into contact with forklifts. This is less of a problem with push back pallets. Also worth mentioning: push back systems work wonderfully with standard forklifts and rarely require specialized vehicles.

Applications are endless for push back pallet racking systems, which can be used in many types of warehouse operations. These storage space solutions are especially common in the following contexts:

- Food storage. Freezer space is notoriously expensive, so it's important to make the most of every inch. Push back systems easily accomplish this, making them the go-to option for warehouses that specialize in frozen food storage.

- Pharmaceuticals. The aforementioned advantages that make push back systems ideal for food storage also deliver excellent results with pharmaceuticals, which often rely on cost-effective, yet highly selective cold storage solutions.

- eCommerce. The versatility and limited honeycombing of push back provides an excellent advantage for eCommerce businesses, which can handle numerous SKUs while maintaining exceptional organization and efficiency.

Warehouse1 Can Help Find a System to Meets Your Needs

Warehouse operations can look significantly different from one facility to the next, so it's crucial that you find a customized solution to help you meet your enterprise's unique goals. With a targeted approach, it's possible to take full advantage of the many opportunities that push back pallet systems offer.

Our experts at Warehouse1 will work closely with you to determine which pallet racking systems are best suited to your facility — and how they can be adjusted to improve productivity. Contact us today to learn more about our pallet racking solutions.