Robotics & Automated Material Handling Systems

TRANSFORM YOUR WAREHOUSE WITH ROBOTICS

TRANSFORM YOUR WAREHOUSE WITH ROBOTICS

In today’s high-velocity supply chain and production environments, the margin for error is razor-thin. Robotics automation helps you scale operations, reduce labor dependency, and achieve unmatched consistency. We’ve partnered with global leaders—KUKA and Addverb—to bring you a suite of integrated robotics technologies for the warehouse, production floor, and distribution center.

WHY ROBOTICS IS A SMARTER SOLUTION

WHY ROBOTICS IS A SMARTER SOLUTION

Modern robotics is no longer aspirational—it’s essential. Companies are leveraging automation to:

- Boost throughput with 24/7 autonomous operation

- Enhance accuracy and quality control

- Improve employee safety by eliminating hazardous manual tasks

- Reduce total cost of ownership through energy efficiency and modular integration

- Gain adaptability with scalable systems that grow with your needs

Top Robotics Solutions We Deliver

Autonomous Mobile Robots (AMRs)

From KUKA & Addverb

Navigate dynamic environments and transport goods efficiently with intelligent AMRs. These robots plan optimal paths, avoid obstacles, and handle complex routing with real-time adjustments.

- Smart navigation with LiDAR and vision-based systems

- Modular payload options

- Easy integration with WMS and ERP platforms

Robotic Palletizers and Depalletizers

From KUKA & Addverb

Automate labor-intensive end-of-line tasks with robust palletizing solutions. Perfect for food & beverage, logistics, and industrial packaging.

- Custom grippers and tool changers

- Adaptive placement algorithms

- Flexible for case packing, depalletizing, and mixed-SKU handling

Robotic Pick and Place Systems

From KUKA & Addverb

Pick multiple SKUs or cartons simultaneously with AI-powered robotic arms trained for fast-moving inventory. Solutions include multi-carton picking robots for high-mix SKU environments.

- Vision-guided picking

- High-payload robotic arms

- Gripper versatility for diverse item shapes

Robotic Sorters and Sortation Systems

From Addverb

Optimize outbound and inbound parcel flow with high-speed sorters. Whether it's vertical sortation or robotic arm-based item sorting, these solutions reduce bottlenecks and ensure parcel accuracy.

- Carton-level precision

- Conveyor-integrated sorters

- Vertical drop sortation in limited space layouts

Who Should Consider Robotics for Their Operations?

Robotics automation isn’t just for large tech companies or fully automated factories—it’s an accessible, high-impact solution for any operation looking to improve efficiency, accuracy, and safety.

If your business relies on consistent material movement, packaging, or order handling, you’re likely to benefit.

Whether you're facing labor shortages, growing fulfillment demands, or seeking to improve ROI on facility investments, robotics can help you:

- Reduce operational costs and errors

- Scale throughput without scaling headcount

- Maintain product quality and traceability

- Adapt to fluctuating demand with modular systems

How Can We Help?

Industries that benefit most

Operations across these sectors deploy robotics solutions to solve real-world challenges:

eCommerce & Fulfillment

Streamline picking, sorting, and replenishment during peak seasons or high SKU complexity environments.

Food & Beverage

Enhance food safety and throughput with hygienic automation for palletizing, packing, and cold-chain logistics.

Automotive & Heavy Equipment

Handle heavy, bulky, or complex assemblies with precision and minimize ergonomic risks on the line.

Cold Storage

Operate in sub-zero conditions where manual labor is costly and limited, while ensuring reliable inventory flow.

Manufacturing

Automate repetitive production tasks, improve quality assurance, and increase production flexibility.

Pharma & Healthcare

Ensure sterility and compliance in order fulfillment, packaging, and handling with minimal human intervention.

Why Warehouse1?

Choosing the right robotics partner is just as important as choosing the right automation system. Here’s why Warehouse1 is trusted by top-tier operations across the country:

Choosing the right robotics partner is just as important as choosing the right automation system. Here’s why Warehouse1 is trusted by top-tier operations across the country:

✔️ Experts in Layout + Robotics Engineering

Our team integrates robotics seamlessly into your operational footprint with smart facility design and flow optimization.

✔️ CAD + Permit-Ready Drawings

We deliver detailed, engineer-reviewed drawings that streamline approvals and accelerate project timelines.

✔️ Agnostic, Vendor-Neutral Recommendations

We work for you—not the manufacturers—helping you select the right robotic technologies for your unique goals and budget.

✔️ Full-Service Project Management & Installation

From planning through commissioning, we manage every phase of implementation with technical precision and responsive communication.

✔️ Partnerships with Leading Robotics Brands

We bring you best-in-class technologies from KUKA, Addverb, and others—fully vetted, integrated, and supported.

Our Featured Robotics Partners

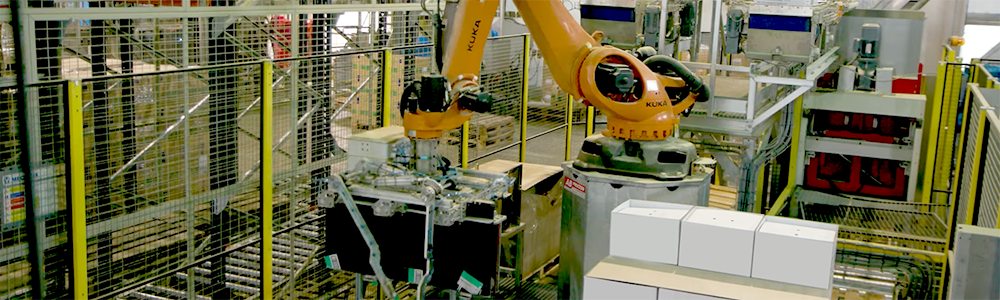

KUKA Robotics

A pioneer in industrial robotics, KUKA delivers highly configurable robots for production automation. From industrial arms to mobile robots with omnidirectional mobility, their offerings are built to scale and integrate seamlessly.

Key KUKA Technologies:

- KMR iisy: Mobile cobot platform

- Industrial 6-axis robots for assembly, welding, and more

- Mobile platforms for logistics and production environments

Addverb Technologies

Known for advanced warehouse robotics, Addverb offers a wide range of automation—from autonomous mobile robots to smart pick and place systems and sorters—all engineered for high-density environments and intelligent operations.

Key Addverb Technologies:

- Dynamo: Autonomous Mobile Robot

- Zippy: Carton Picking Robot

- SortIE: Robotic Sorter

- Veloce: Vertical Sortation Robot

Real Results with Real Clients

Robotics Case Studies

| Yuengling Palletization Case Study KUKA |

DHL Sortation Case Study Addverb |

AMR Comparison Case Study KUKA |

|

|

|

Ready to Explore Automation?

Book a Free Robotics Consultation

Get expert insights on the best-fit robotics solution for your operations. Whether you’re exploring AMRs, sortation systems, or palletizers, we’ll guide you through system design, integration, and ROI modeling.