Warehouse Safety Tips: Keep Your Employees Safe

Warehouses are one of the few places where work-related injuries can be almost completely avoided. A low-injury work site means an efficient team who will keep the warehouse running smoothly and prevent accidents. Within this article, we will explore the following warehouse safety tips:

Warehouses are one of the few places where work-related injuries can be almost completely avoided. A low-injury work site means an efficient team who will keep the warehouse running smoothly and prevent accidents. Within this article, we will explore the following warehouse safety tips:

- Keep safety top of mind

- Training employees on preventing accidents

- Proper dress

- Organization in the warehouse

- Staying safe in the winter

- Incentive-based workplace safety programs

- Safety Basics for workers

Keep Safety Top of Mind

Keep an eye on warehouse equipment and space, and don’t overlook the obvious. Regularly check scaffolding and ladders to guarantee they’re built correctly and can hold adequate weight. Inspect all tools and equipment to ensure they are working properly and don’t need to be repaired or replaced. Have a “see it, grab it” policy to keep floors clear of hazards.

Have a “see it, grab it” policy to keep floors clear of hazards.

Oftentimes, the small or obvious mistakes are what cause the most injury. This is where creating and displaying a warehouse safety checklist could be extremely useful to ensure no checks are skipped or overlooked. Most importantly, everyone should receive proper training for working around any machine that requires specific knowledge for handling, especially those with an auger or press.

Accident Prevention Training is Key

When falls happen that could have easily been prevented, the consequences can feel more devastating. Simple safety precautions and training required by OSHA can minimize the risk of workplace accidents. Businesses should:

- Understand regulatory requirements and make compliance a priority.

- Invest in ANSI qualified trainers to conduct safety seminars and training.

- Educate workers on safety requirements and the right way to set up safety equipment.

- Encourage employees to speak up when safety standards are not being followed.

- Have employees take a post-training test to ensure retention of the material.

- Encourage employees to attend internal and off-site fall prevention and safety training seminars.

Dress for the Part

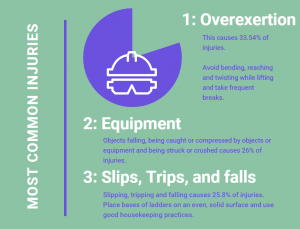

Statistics state slips and falls account for about 26% of cost-influencing injuries in warehouses, so insist on non-slip shoes for all workers.

Statistics state slips and falls account for about 26% of cost-influencing injuries in warehouses, so insist on non-slip shoes for all workers.

Inspected safety gear, such as harnesses for working in high places, should be used. Ensure everyone wears hard hats and safety goggles on the floor.

Reorganize the Space

Make sure containers, boxes, and lumber are all stacked appropriately to prevent them from tumbling over. Improperly housed products that fall unexpectedly are the most common cause of warehouse injury.

When possible, moving vehicles, forklifts, and machines should be kept outside or on the loading docks. Consider removing the lowest level on multilayer racks so employees aren’t having to bend as low. Continuously analyze and change the layout as needed to improve efficiencies and proactively prevent injuries.

Safety in the Winter

With colder weather comes freezing temperatures, ice, and melted snow in and around the warehouse. Here are a few tips specific to cold weather safety in the workplace:

- Ice on staircases, ladders and in parking lots pose huge dangers, so remind employees to tread lightly and walk slowly. Put up signs to warn employees of ice, and place salt in icy areas where people will be walking. Consider placing towels around the space so staff can easily wipe up water.

- If employees are sick with the cold or flu on the job, they can infect multiple people. When someone falls ill, make sure to advise them to get plenty of rest, take proper medication, and drink water.

- When working outside or in cold weather, the internal heat your body musters can make you feel warmer than you are. Hypothermia occurs when your body temperature dips under 95 degrees. Advise workers to wear extra layers, especially on their hands and feet.

- Doing physical labor in the cold tends to make your heart work extra hard. Have them take it easy when the conditions worsen.

Incentive-Based Warehouse Safety Programs

While safety measures like netting can help, they are often not enough. Many employers today are turning to incentive-based safety programs to improve safety.

While safety measures like netting can help, they are often not enough. Many employers today are turning to incentive-based safety programs to improve safety.

Workplace safety training should include information on equipment handling, tool selection, safety gear, and appropriate dress in a hands-on learning environment. Simulations are effective in promoting material retention. With a two-pronged approach focused on written material and real-world experience, companies can train their employees to adhere to safety protocols in the workplace.

Creating a Program

Many companies have successfully used gift card rewards, cash prizes, extra time off, and company-branded merchandise to encourage participation. Another part of a program that will make the process more meaningful for employees is a method for recognition. While your program doesn’t have to be extravagant, a regular recognition event with catered food and an update from management can create a feeling of unity.

Many companies have successfully used gift card rewards, cash prizes, extra time off, and company-branded merchandise to encourage participation. Another part of a program that will make the process more meaningful for employees is a method for recognition. While your program doesn’t have to be extravagant, a regular recognition event with catered food and an update from management can create a feeling of unity.

A safety program can focus on something as simple as rewarding those who have gone without injury over a specified timeframe. However, you do not want to discourage employees from reporting an injury.

The Effects of a Program Over Time

A safety incentive program at your company is a low-cost way to encourage best practices. By investing a small part of your budget in incentives, you are also investing in your employees’ health and productivity. You may start to see long term benefits in the form of decreased injury claims and increased employee attendance.

The Safety Basics

Even simple information can make a difference when it comes to warehouse accident prevention. Here are some basic safety tips for warehouse workers:

- In 2017, there was a 4.5% increase over the previous years in slips, trips, and falls among factory workers. Floors can be slick, damaged or uneven. Be sure to take extra care in avoiding obstacles and keeping your shoes dry.

- On a positive note, there was a decrease of 8.7% in 2017 with accidents related to objects and equipment falling. No one can predict when an object falls from above, so make sure to wear protective headgear, such as a hardhat. A hardhat’s design allows inner suspension with roughly an inch in between the hat and the head, allowing shock absorption when impact occurs.

- Accidents reported from fires and explosions increased 40% in 2017 from 2016! Make sure your factory is up to date on their prevention policy and practice fire drills to ensure a good exit strategy.

- Make sure you’re doing your due diligence in protecting employees and yourself from machine-related injuries. Many painful wounds are preventable by making sure you do your best to keep your machines safeguarded.

- Day to day muscle strains, bumps and bruises, and other ergonomic injuries are not always serious and are preventable. Make sure you avoid back and leg injuries by recommending stretching, eating healthy, and not over-exerting yourself.

The Cost of Ignoring Safety

Businesses who fail to make warehouse safety procedures, programs, and rules a top priority may have to deal with numerous consequences caused by workplace fall accidents. Falls that are fatal or cause serious harm in the workplace can cost businesses thousands of dollars in workers’ compensation insurance, regulatory body fines, and lawsuits.

Businesses who fail to make warehouse safety procedures, programs, and rules a top priority may have to deal with numerous consequences caused by workplace fall accidents. Falls that are fatal or cause serious harm in the workplace can cost businesses thousands of dollars in workers’ compensation insurance, regulatory body fines, and lawsuits.

In addition to the steep price tag an accident can have, the emotional strain on the team can weaken productivity and hurt overall morale. Some businesses may never recover from the financial and emotional burden of a fall accident. A business owner may even face criminal charges after some preventable accidents. Overall, warehouse safety topics should not be overlooked but rather a major focus for owners and employees.

For more information on how we can help with your warehouse safety, contact our team at Warehouse1 or browse our selection of material handling products that promote safety.