Pallet Rack Inspection for Damage

A warehouse can be a dangerous environment. Forklift trucks are constantly moving through aisles of pallet racking, moving inventory on and off the shelves. Sometimes, they may bump into these pallet racks, and the forklift impact causes damage that needs to be repaired. In fact, just misplacing a pallet when inserting onto the rack can cause damage.

Storage racks are an integral piece of material handling equipment, and they depend on their original manufactured shape for structural integrity. Once the form is compromised, the load capacity of the member is reduced. The majority of rack damage occurs incrementally rather than abruptly.

This is why pallet rack inspection should be performed regularly. These small pallet rack issues, if not fixed, can lead to extremely damaged rack components making the structure as a whole no longer safe.

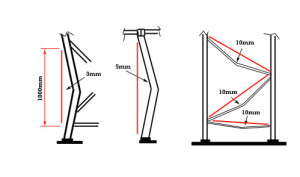

The easiest damage to detect is when a column has been broken from one major impact. It is more difficult to identify the structural damage an upright or beam has sustained from minor impacts over time. While the rack may appear only slightly dented, it may be in need of immediate repair.

A tenth of an inch dent over a 40 in. area is enough to take away 25% load capacity, making the rack unsafe.

With minor damaged components, the frame may still support some unknown capacity, but it will not support the maximum capacity it was designed for. This can be hazardous if the rack is needed to support heavier loads in the future. You might be asking yourself, “what small damages should I be looking for?”. It is important for you to inspect both the front and rear of your frames and inspect the primary parts to look for signs your pallet rack is damaged.

How to Inspect and Find Pallet Rack Damage

- Step 1: Check your Upright Columns – These are the towers at the front and rear of the upright that are connected by bracing. Review for any twisting of the uprights.

- Step 2: Check your Baseplate – The uprights sit on your baseplate and usually have one or two anchors. Make sure they are secure to floor and free of twists or other damage.

- Step 3: Check your Anchor – These are the bolts that anchor the racking to the floor. Anchor bolts can be missing, sheared, or dislodged from truck impact.

- Step 4: Check your Shims – Shims help level the rack system under the baseplate. If shims are showing, it will indicate the upright has moved or twisted.

- Step 5: Check your Bracing – Horizontal and diagonal bracing make up the frame along with the two upright columns. Although in the middle of the frame, damage still occurs here so be sure to check for secure bracing.

- Step 6: Check your Beams – Beams will naturally deflect (or bend) under load, and excessive deflection may indicate overloading. Check your beams for bending, and replace or repair as necessary.

Doing a regular inspection of your storage rack could save you time and money, preventing inventory damage or loss, and injury to employees. It is recommended that you inspect pallet racking annually at minimum for warehouse safety reasons, but inspecting more often will increase your chances of catching damages.

Need someone to do an inspection for you? Need pallet rack repair or replacement? Contact Warehouse1 today to speak to an expert about how you can get the most out of your pallet racking systems.