Pallet Rack Identification Guide

Pallet racking forms the backbone of the modern warehouse. These systems maximize storage space while allowing for the safe and easy retrieval of critical items. To the outsider, pallet racks all look alike — but upon close observation, you'll notice that each system has its own unique structure, with differences including everything from the type of steel to the shapes of the keyhole punches and even where these are situated.

Pallet racking forms the backbone of the modern warehouse. These systems maximize storage space while allowing for the safe and easy retrieval of critical items. To the outsider, pallet racks all look alike — but upon close observation, you'll notice that each system has its own unique structure, with differences including everything from the type of steel to the shapes of the keyhole punches and even where these are situated.

Seemingly small distinctions can make a world of difference for pallet racking systems, influencing how easy they are to set up and how durable they'll prove in the long run. Below we'll provide a deep dive into all things pallet racking: which components are included, how these differ between various designs, and which manufacturers and products are most trusted.

The Basics of Pallet Racking

Featuring horizontal rows that may occupy multiple levels, pallet racking systems are designed to store pallets, which are flat structures designed to keep goods stable. The pallet racks consist of uprights and beams, which form heavy-duty, yet adaptable storage structures. The basic function of this material handling solution is to store items in a way that maximizes available space while also promoting effective organization and efficient retrieval.

Pallet Rack Styles and Their Identification

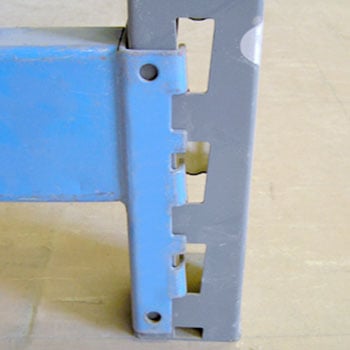

Despite their apparent simplicity, pallet racks come in many different forms. Their distinctions are typically most evident based on the size and shape of the punch holes located in the upright columns.

It is important to pay close attention to pallet rack styles when selecting beams and uprights, as these will not always be compatible with one another. This can be true even when pallet components share the same name but is especially likely when investing in used pallet racks.

Struggling to tell different pallet rack systems apart? Below, we've highlighted a few of the main pallet rack styles you can expect to encounter:

Teardrop (old style). The teardrop style has long been a trusted option. The original version of the teardrop featured holes in the uprights resembling upside-down teardrops. This design was meant to make the beams and uprights more secure. This was originally manufactured by Interlake but has since been adopted by many manufacturers due to its versatile design.

Teardrop (old style). The teardrop style has long been a trusted option. The original version of the teardrop featured holes in the uprights resembling upside-down teardrops. This design was meant to make the beams and uprights more secure. This was originally manufactured by Interlake but has since been adopted by many manufacturers due to its versatile design.

Teardrop (new style). After the original teardrop patent expired, Interlake created a newer design with hole shapes departing from the original upside-down teardrops. The new version's holes have more of a rectangular shape, but with a slight taper near the bottom. New style teardrop beams fit into old style uprights.

Teardrop (new style). After the original teardrop patent expired, Interlake created a newer design with hole shapes departing from the original upside-down teardrops. The new version's holes have more of a rectangular shape, but with a slight taper near the bottom. New style teardrop beams fit into old style uprights.

Teardrop (Mecalux punched style). Designed to work with other uprights and manufacturers, the Mecalux punched teardrop makes the most of the distinct upside-down teardrop shape. This unique option involves bolting the uprights together, rather than relying on welding.

Teardrop (Mecalux punched style). Designed to work with other uprights and manufacturers, the Mecalux punched teardrop makes the most of the distinct upside-down teardrop shape. This unique option involves bolting the uprights together, rather than relying on welding.

Structural. Fabricated by hot-rolling structural steel channels, structural pallet racks can withstand a lot of wear and tear in harsh environments. This is a preferred option when heavy pallet loads are required. Made by many manufacturers, structural rack beams and uprights bolt together.

Structural. Fabricated by hot-rolling structural steel channels, structural pallet racks can withstand a lot of wear and tear in harsh environments. This is a preferred option when heavy pallet loads are required. Made by many manufacturers, structural rack beams and uprights bolt together.

T-bolt. The T-bolt system features a rigid connection between the beam and the upright. These are usually easy to install, with the head inserted into the connector and column and then locked into place. A patented locking system prevents the bolt from disengaging when heavy loads are required.

T-bolt. The T-bolt system features a rigid connection between the beam and the upright. These are usually easy to install, with the head inserted into the connector and column and then locked into place. A patented locking system prevents the bolt from disengaging when heavy loads are required.

Ridg-U-Rak slotted. Hook and slot beam-to-column connections distinguish the Ridg-U-Rak slotted system, which features six-bend, roll-formed columns that are meant to be as rigid and durable as possible.

Ridg-U-Rak slotted. Hook and slot beam-to-column connections distinguish the Ridg-U-Rak slotted system, which features six-bend, roll-formed columns that are meant to be as rigid and durable as possible.

Keystone. Also known as Republic pallet racks, Keystone designs have clip hooks with square tops, which are believed to allow for impressive strength-to-weight ratios. This boltless approach is also meant to optimize space and enhance efficiency.

Keystone. Also known as Republic pallet racks, Keystone designs have clip hooks with square tops, which are believed to allow for impressive strength-to-weight ratios. This boltless approach is also meant to optimize space and enhance efficiency.

Speedrack. As a top pallet racking supplier, Speedrack originally made its mark with a tubular design but has since been most noteworthy for its contributions to the eCommerce sector. A system of handle clips and J-hook pins limits the potential for detachment.

Speedrack. As a top pallet racking supplier, Speedrack originally made its mark with a tubular design but has since been most noteworthy for its contributions to the eCommerce sector. A system of handle clips and J-hook pins limits the potential for detachment.

Harder to Find/Discontinued Styles

Many of the pallet racking solutions outlined above have been around for decades — but they remain as popular as ever. Other racking systems, however, can be more difficult to find. Some are manufactured abroad, while others have long since ceased production. Below we've provided details on several tough-to-find styles.

Dexion. Dexion standard pallet racks incorporate an inverted teardrop slot design, with round pins automatically locking in place at the narrow portion of the teardrop shape.

EMI. EMI is unique with diamond shapes for the holes including snap locks and clinch-roll beams with triple-thickness at the top.

EMI. EMI is unique with diamond shapes for the holes including snap locks and clinch-roll beams with triple-thickness at the top.

Engineered Products. Compatible with a variety of major pallet racking brands, these pre-engineered boltless systems provide access to multiple connector designs, so rack elements can be interchanged as needed.

Frazier. As a leading producer of structural style racking, Frazier is best known for its Sentinel® system, which provides the best of both worlds: it's relatively easy to install and adjust, yet incredibly durable due to its use of structural steel. Thick gauge metal columns and strong channel corners lend these pallet racks a unique rugged appeal.

Frick Gallagher. No longer in production, these pallet racks can be incredibly difficult to find. The keyhole desgin on 4" centers associated with this pallet rack system resembles today's dominant teardrop designs.

Hallowell. Accommodating bulky items or high-clearance needs, Hallowell uprights feature keyhole slots that align with the beam rivets and allow for tight assembly.

Hi-Line. Round holes and unique space-saving solutions set Hi-Line products apart. Although these are roll-formed systems, they are of a heavier gauge due to the spacing of the holes.

Husky. Featuring teardrop punches and two-inch centers, bowlock safety clips provide peace of mind, allowing for taller builds without splicing.

Konstant. Konstant constructs customizable solutions from hot-rolled structural steel. Welded and bolted options are available to promote maximum versatility.

Lynx. This double-slotted solution involves three-inch centers and safety catches that are capable of mechanically locking into place. These systems are compatible with other double-slotted designs.

Lyon. MIG welded, incorporating cross-channel reinforcements to promote strength. The beams can be adjusted via tapered keyhole slots. Teardrop designs make these interchangeable with many other pallet-racking systems.

M-I-Rak. Positive locking device prevents accidental dislodging of beam while still allowing for adjustments. M-I-Rak is no longer manufactured and hard to find in the used market.

M-I-Rak. Positive locking device prevents accidental dislodging of beam while still allowing for adjustments. M-I-Rak is no longer manufactured and hard to find in the used market.

Pacific. Featuring a three-lock system known for durability and ease of installation. Pacific pallet racks are not currently manufactured.

Paltier. Like the Interlake teardrop systems referenced earlier, Paltier is divided into older and newer styles, distinguished by the shapes of the holes. For the older styles, these are more angular. The newer version is more rounded at the top.

Paltier. Like the Interlake teardrop systems referenced earlier, Paltier is divided into older and newer styles, distinguished by the shapes of the holes. For the older styles, these are more angular. The newer version is more rounded at the top.

Penco. Equipped with three-prong connections, safety lock tabs prevent dislodging, with the recessed safety key made highly visible.

Redirack. Redirack solutions come with six-point connections. These racking systems are highly customizable, and therefore, the go-to option for many Canadian enterprises. Redirack systems are more difficult to obtain in the U.S.

Redirack. Redirack solutions come with six-point connections. These racking systems are highly customizable, and therefore, the go-to option for many Canadian enterprises. Redirack systems are more difficult to obtain in the U.S.

Sammons. Don't be confused by the hole shapes for these pallet racks, which resemble prominent teardrop designs. With Sammons, these involve four-inch centers and are strictly compatible with mushroom-shaped pins.

Slide N Lock. Featuring upright designs that utilize cotter pins, Slide N Lock pallet racks are now nearly impossible to acquire.

Slide N Lock. Featuring upright designs that utilize cotter pins, Slide N Lock pallet racks are now nearly impossible to acquire.

Sturdi-Bilt slotted. The Sturdi-Bilt system relies on a wedge lock clip system to keep beams in place. A strong friction connection promotes a degree of rigidity.

Webb-style. Sometimes referred to as Prest, both are follow up designs to the Slide N Lock style with the uprights having vertical slots.

Other difficult-to-acquire pallet solutions include:

- Artco

- Amerlock

- Amer Rack

- Burtman

- Frontier

- Inca-Backbone

- Master Rack by Buckley

- NEDCON

- Palmer-Shile

Pallet Rack Specifications & Components

While the many styles outlined above reveal just how significantly pallet racks can differ, there are a few central components worth mentioning:

- Uprights. Vertical towers known as uprights form the basis of pallet racking systems. Each rack bay incorporates two uprights.

- Beams. Responsible for linking vertical uprights, beams are rugged, load-bearing structures that promote effective shelving.

- Wire decking. Situated above cross-beams, wire decking provides support to ensure full safety. It's constructed from metal mesh and can be a great option for non-palletized items.

How Warehouse1 Can Meet Your Unique Pallet Racking Needs

Does your pallet racking system need specific upgrades? Or are you ready to start from scratch? Either way, the team at Warehouse1 can help you find the specific structures you need to improve warehouse efficiency, storage, and safety.

At Warehouse1, we offer a variety of pallet rack systems and accessories, plus insight into the best solutions for every situation. We're happy to help you design or locate the perfect pallet racking setup. Reach out today to learn more.