Why Should I Buy Drive-In or Drive-Through Rack?

Drive-in and drive-through pallet rack systems provide an efficient answer to high-density storage requirements.

How Drive In and Drive Through Racks Work

In these configurations, a forklift drives into the rows of racks from one side only in a drive in rack system, or from either side in a drive-through system, to add or retrieve movable pallets placed on rails. The pallets are placed on the rails to be stored deep in the system. This method greatly reduces the number of aisles necessary for access and the storage capacity of a drive-in/drive-through pallet rack is often limited only by size of your facility. In the same footprint of floor space, approximately 75% more pallets can be stored in a drive-in/drive through system than in a selective rack system.

|

|

Drive-in and drive-through rack systems can store 75% more pallets than selective rack due to higher storage density and less aisle space. In a drive-in racking system, pallets are loaded and unloaded from one side of the racks only. The forklift drives into the rack system from that side, loading or retrieving sliding pallets on the rails. This configuration is normally utilized in consistent LIFO (last in, first out) inventories or bulk stock that has no time sensitivity or aging considerations.In a drive-through racking system, pallets are loaded from one side and unloaded from the other side by trucks driving into the racks and loading/unloading on rails. This configuration is normally used for FIFO (first in, first out) inventories and ensures fast stock rotation. |

Benefits of Drive-In and Drive-Through Racking

The benefits of drive-in/drive-through pallet racks are many. Here are a few of the pluses:

- Drive-in/drive-through adapts best to large volume storage of products with the same SKU.

- Installation of either system is straightforward and utilizes easily mounted support arms to add the load rails to the rack structure.

- Drive-in racks provide the highest density storage available in any pallet rack system.

- Drive-in racks can be installed in conventional warehouses with no overhead attachment. They can also form the supporting infrastructure in buildings which are supported by the racks.

- Drive-through racks derive stability from either an overhead ties or from overhead attachment to the building structure. This makes them well-suited to installation in freezers.

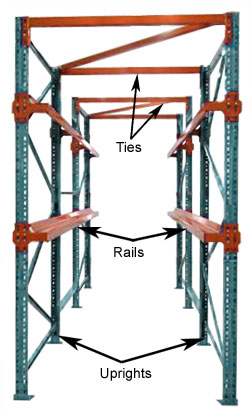

Drive-in and drive-through rack systems consist of uprights, rails and tiesUprights form the vertical structure to which rails connect, creating shelf levels for pallet storage. Ties provide structure for the system.

- Upfront cost is higher than selective rack . A drive-in installation costs up to $20 to 30 more per pallet than selective rack, while drive-through is $30 to 50 more per pallet than selective.

- Drive-in/drive-through systems are usually subjected to high strain and abuse from both lift trucks and loads during normal daily usage.

- Any one pallet may not be easily accessible at a given time. Stock must be strictly limited to like items only without the need for unrestricted picking of specific pallets.

|

| Upfront cost compared to selective rack, high abuse from lift trucks and limited access to some pallets are a few drawbacks of drive-in and drive-through rack. |

Final Word

Drive-in and drive-through rack systems work best in applications with fewer SKUs and space shortage issues.